Silica Gel Desiccants: A Strategic Moisture Control Solution For Large Industries

For large manufacturing plants, utilities, and exporters, moisture is not just a small quality issue, but a million-dollar risk. If silica gel desiccants are correctly designed, downtime, product rejection, and warranty claims can be dramatically reduced.

Why Moisture Control Is A Board-Level Issue

High humidity is the main driver of corrosion, short circuits, caking, fungal growth, and product degradation in transformers, control panels, petrochemical lines, bulk packaging, and export containers. Studies show that controlled humidity packaging and storage significantly improve product shelf life, electrical reliability, and mechanical integrity, especially in pharma, electronics, and chemicals.

For large industries, this risk is not limited to material loss; brand reputation damage, regulatory non-compliance, and supply-chain disruption are also directly linked to moisture. Therefore, it is essential to treat moisture control as a strategic reliability and quality pillar, rather than just a “put in a packet” level decision.

How Industrial Silica Gel Actually Works

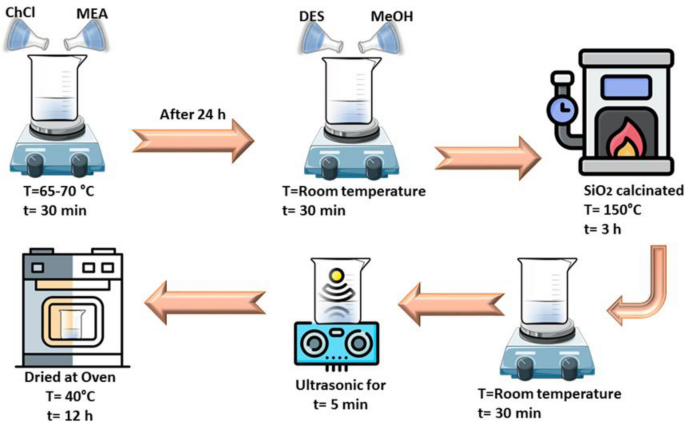

Silica gel is a synthetically produced, highly porous form of silicon dioxide with a dense network of microscopic interconnected pores inside it. These pores bring the surface area up to 600–800 m²/g, due to which the gel can adsorb a significant portion of its weight in the form of moisture.

Moisture adsorption is a surface phenomenon: water molecules continue to bond inside the pores until equilibrium is reached. By choosing different pore-size distributions (Type A, B, C, granular, beaded, indicating, non-indicating), process engineers can target specific humidity ranges, for example low-dew-point compressed air vs ambient-temperature warehouse storage.

Key Industrial Applications Beyond Small Packets

Silica gel desiccants are usually associated with small sachets, but in large-scale industry, they are used through engineered systems. Bulk beads, granules, and powder are integrated into packed beds, cartridges, breather units, and custom assemblies.

Some high-value use cases:

- Petrochemical & Gas: Packed-bed dryers and pressure swing adsorption (PSA) units remove moisture from natural gas, process air, and instrument air, significantly reducing pipeline corrosion and catalyst deactivation.

- Power & Utilities: Transformer breathers use silica gel so that ambient moist air, which is drawn into the tank with oil expansion, is dried first and the insulation system's paper/oil remains healthy.

- Electronics & Semiconductors: Cleanroom storage cabinets and dry boxes maintain stable humidity with silica gel-based systems, improving the reliability of PCBs, wafers, and sensitive sensors.

Selecting The Right Type Of Silica Gel For Your Plant

“One-size-fits-all” desiccant does not work for every plant, so type selection is a critical part of the design phase. Non-indicating regular gel is suitable for high-volume industrial drying, while blue/orange indicating beads visually inform maintenance teams that it is time for regeneration.

Granular silica gel is useful for high airflow and fast adsorption, for example in large desiccant tanks or breathers; beaded silica gel provides uniform packing, predictable pressure drop, and consistent moisture breakthrough time. Specialty grades, such as narrow-pore or wide-pore silica, address specific humidity windows (e.g., low-RH protection vs high-RH bulk drying).

Operational Best Practices: From Design To Regeneration

An effective silica gel solution is created not just from the product, but from system design. Engineers should calculate the application's humidity range, airflow, temperature, residence time, dew-point target, and expected moisture load to define bed sizing, cartridge design, and refill frequency. Many reputable suppliers offer application engineering support, moisture load calculations, and pilot testing.

Regeneration strategy is also a key part of the business case. Silica gel is typically regenerated at 120–150 °C using an oven or in-situ heaters; heating for 2–4 hours on a thin bed or tray recovers a major portion of the adsorption capacity, allowing the same material to be reused for dozens of cycles. Proper cooling in sealed containers and FIFO inventory management keep performance consistent.

Safety, Compliance And Environmental Considerations

Industrial-grade silica gel is chemically inert, non-flammable, and non-toxic for general use, which is why it is globally accepted in food, pharma, and electronics supply chains. Health-and-safety risks are mainly related to dust inhalation and improper handling, which can be controlled with suitable PPE, training, and housekeeping.

For large organizations, the supplier's quality framework is critical. ISO 9001 and ISO 14001 certified manufacturers typically follow strict standards for pore-size distribution, adsorption capacity, particle-size uniformity, and environmental controls. In-house QA labs and traceable batch testing ensure that every shipment delivers predictable performance – essential for validation, audits, and regulatory inspections.

How To Evaluate A Silica Gel Partner For Enterprise-Scale Use

When plants consume multi-ton per year of silica gel, vendor selection becomes a strategic sourcing decision. The ideal partner not only supplies the product but also provides design support, testing protocols, documentation, and after-sales technical assistance. Leading manufacturers offer bulk drums, super sacks, containerized quantities, and even rail-car shipments, optimizing logistics costs.

Key points for evaluation:

- Technical Fit: Lab data available for required bead/powder grade, pore size, indicator type, mechanical strength, dust levels, and regeneration behavior.

- Engineering Support: Moisture load studies, pilot trials, packed-bed design recommendations, and troubleshooting assistance, so the solution rises above a “commodity packet” to an engineered system.

- Commercial Reliability: Consistent lead times, global delivery capability, clear minimum order quantities, and competitive per-kg pricing directly impact long-term TCO.

From Commodity To Engineered Advantage

For many plants, silica gel is still a low-involvement consumable, while data clearly shows that selecting the right grade, right design, and right partner can markedly reduce scrap, failures, and downtime. Treating industrial desiccants as a core part of reliability engineering, asset management, and export-quality strategy creates a competitive edge.

If your organization handles high-value equipment, sensitive products, or global shipments, now is the best time to reassess your moisture control strategy – based on laboratory data, field performance, and lifecycle economics. Adopting silica gel desiccants from an engineered perspective strengthens your plant availability, product quality, and customer trust in the long term.